Focus

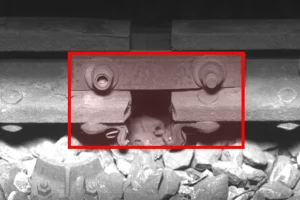

Line-scanning data captured by the AIVR Focus system provides an incredibly comprehensive capture of the track using underbody cameras, allowing proactive maintenance to reduce faults on the tracks.

A Line Scanning System

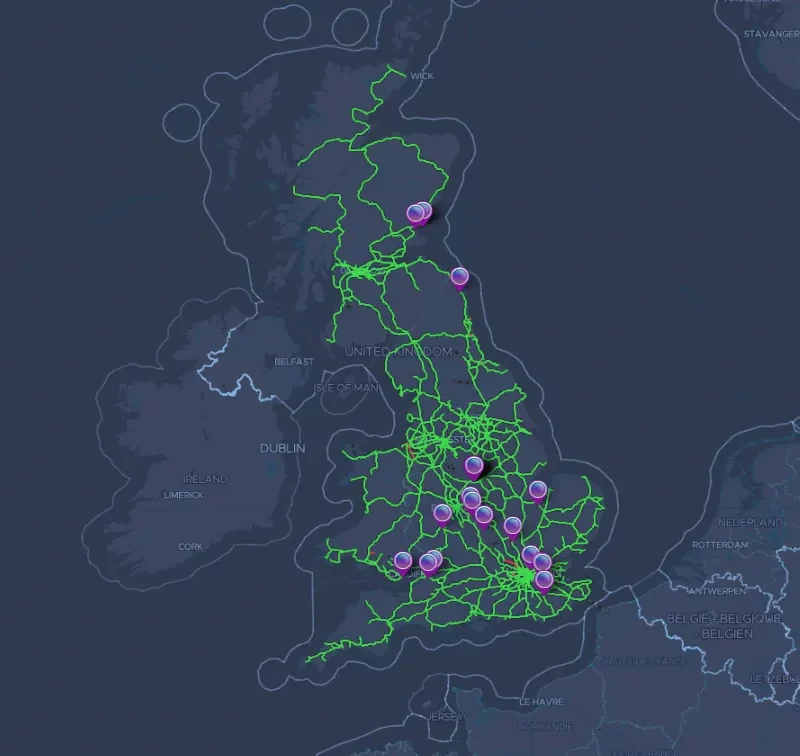

AIVR Focus is a Line Scanning system deployed on in-service and measurement vehicles which automatically captures and transmits track conditions, enabling remote, detailed inspection using a safe, rapid and reliable method.

AIVR Focus can be used to inspect plain line and conductor rail track, allowing proactive maintenance to reduce faults on the tracks.

Track Componentry Detection

Line-scanning data captured by the AIVR Focus system provides an incredibly comprehensive capture of the track using underbody cameras.

Machine Learning is applied to the high-definition imagery to automatically detect componentry such as fishplates, electrical cables, welds, and further points of interest. As more data enters the system, the conditions of these assets can be assessed and highlighted as an ‘issue’ for further investigation.

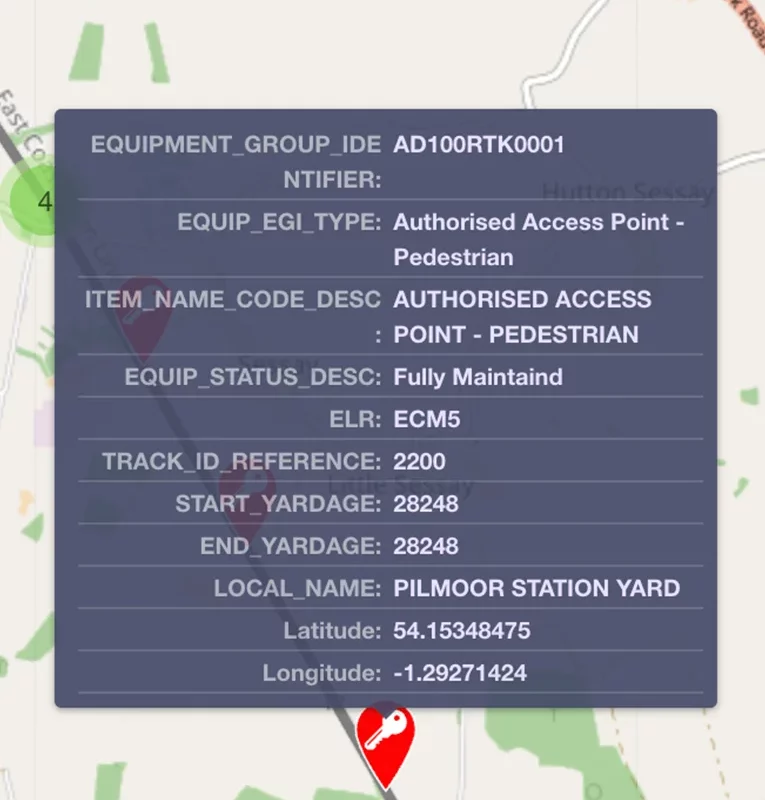

Combined with FFV, geospatial and additional partner location systems, AIVR Focus gives users the ability to determine the exact location where there may be defects, unknown objects or wet beds on the track. This allows maintenance teams to make data-driven decisions to support track maintenance planning and target exact areas which need a rapid response from the team.

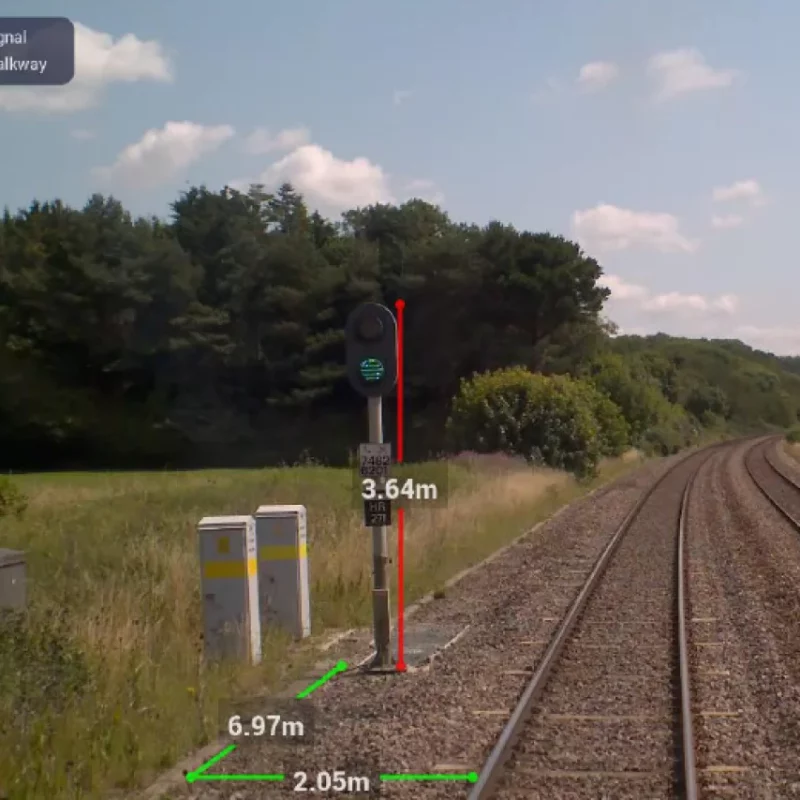

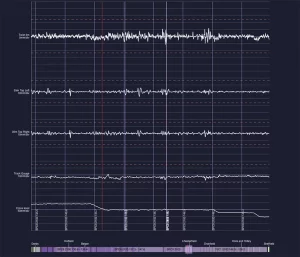

Track Geometry

Laser-based track geometry systems are integrated with AIVR Focus and operate autonomously. Data is made accessible via our powerful web-based frontend alongside AIVR captured line-scanning imagery. Geometry data is provided in Network Rail specific presentation.