11/03/2021

Machine Learning and its Potential in the Rail Industry

Machine learning is the study of computer algorithms to find patterns in data to predict future outcomes. It enables computers to carry out tasks that, up until now, had to be completed by humans.

Rather than having to trawl through old data which may no longer be relevant, machine learning allows you to dip into a current map of assets and conditions. Being able to access current data which gives a snapshot of an event in real-time is incredibly valuable in safety-critical industries like rail.

In One Big Circle’s case, machine learning accelerates the capability of what you can do with video by showing you events, anomalies and inconsistencies you may not instantly spot with the naked eye or be able to interpret and understand at speed. Our AIVR video technology enables you to study, automate, then provide more insight into the data collected. The system can pull out and highlight certain pieces of data that are not always seen during a manual review, such as graffiti in hard-to-access rural areas.

Benefits for the rail industry

The use of machine learning in the rail industry is growing and has massive potential. It’s revolutionising the way rail projects are being carried out, which is not only beneficial for contractors but passengers as well. Combining machine learning capability with the expertise and insight of engineers such as Signalling Innovations Group within Network Rail creates a very dynamic and industry effective result.

By using data to spot patterns and predict accurate forecasts, it allows construction projects to speed-up, and service reliability to improve. Delivering efficiencies in this way contributes to a safer and more resilient railway with less interruptions to passengers.

Machine learning is equally useful for maintenance tasks, as it enables workers to react extremely quickly to any challenges that arise. Having the capability to automatically identify issues can not only prevent major incidents before they occur but also put a stop to the need for engineers to go out on-site to flag areas of concern, which ultimately increases safety, saves time and reduces costs.

For example, let’s say you were facing the issue of detecting potential failures on third rail. By using a thermal sensor the machine learning can uncover where the electrical fault is, based on spikes in temperature, so that it can be dealt with before it escalates into full failure. It might be that the component is overheating but not failed, so being able to pinpoint this quickly means teams can be sent out to respond to the exact piece of track before it results in lines that are out of action.

Another key benefit of leveraging machine learning in rail is the ability to extract valuable insights so that humans have as much knowledge as possible and can respond to events in the correct way, equipped with the right kit.

In addition to train-mounted cameras, One Big Circle partnered with The Manufacturing Technology Centre to create an intelligent surveillance system, which monitors anti-social behaviours at train stations to enhance safety and reduce delays.

Deploying the machine learning onto the incumbent CCTV system enables station staff to spot unusual behaviour and suspicious objects in defined zones, such as restricted areas. If it detects unusual behaviour in that area, it will automatically raise alerts to the operators who can then determine whether it’s a cause for concern. It essentially arms station staff with the knowledge about what they’re tending to so they can deal with a situation in the most appropriate and prepared manner.

Unleashing its potential

The volume of data that can be collected for machine learning technology is highly advantageous for the industry. You need to train the data and then keep running models to check it’s reducing the frequency of false positives before operationally using it. The more data that’s available, the more you can teach the data to predict the outcomes, and the more problems you can resolve as a result.

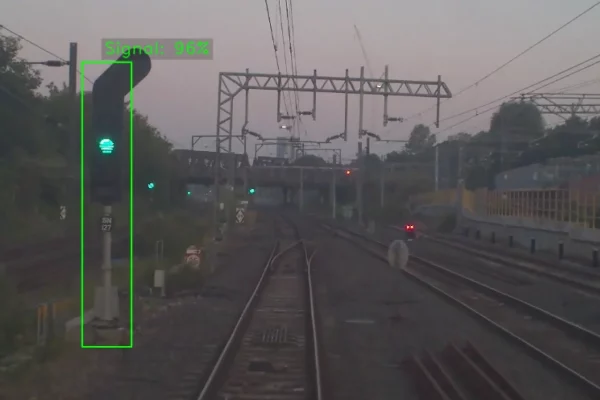

Working with Network Rail engineers and specialists groups within the organisation we’ve trained AIVR to understand what a signal is, or what graffiti is – so it can detect issues and assets and flag any areas that may require further inspection.

Another natural next step is to activate the technology with other workstreams. The data collected from AIVR means every piece of graffiti spotted for example can be packaged into that workflow and sent to the graffiti team so that they don’t have to send workers out to make initial observations, but can be sent to the right locations with the right equipment, ready to tackle the job at hand.

Collaboration in the industry

Collaboration and machine learning go hand in hand. In an industry with tight restraints, there’s not always been a huge amount of data available to train models for machine learning. AIVR needs a lot of data to train on multiple journeys and in mixed environments, lighting conditions and seasons, and we’re fortunate that the amount of data that AIVR collects enables that. But there are challenges in the industry as a whole to obtain enough data to train models and source new data to test it out.

Partnership working, working closely with the industry experts, and encouraging data to be appropriately shared across the network, is vital in moving forward. Getting as many solutions on board as possible will greatly enhance the scope in which we can use machine learning in rail, helping to meet multiple challenges and provide a safer, more efficient rail environment.